Products

Did you know that Space Engine Systems has several spinoff products? We design, manufacture, test, and install several products in the space, aerospace and industrial applications.

Partner with us for a single stop solution to all your most difficult engineering challenges of design, manufacture, testing and installations. Product offerings include:

Custom designed turbine engines for specific applications - Patents Pending in some areas

Custom drone design using turbo-ramjet

Thermal Management for extreme heat including cooling systems for any application including your major computer systems for space, aerospace and industrial applications

Constant Velocity Joints for automotive or industrial applications

Cryogenic extremely light tanks for Liquid Hydrogen for automotive or other industries

Cryogenic systems for Liquid Hydrogen

Turbo Pumps for cryogenic application

Custom designed extremely light and high load tested gears and gearing systems for any application mainly for space and aerospace applications.

Custom switched reluctance motor (22,000 rpm)

Below is a sampling of our products. To inquire about any of these products, please head over to our contact page and send us a message. Space Engine Systems maintains a third-party certified AS9100 Quality Management System and is registered in the Canadian Controlled Goods Program.

Positive Displacement Pumps

Geared design with dry-running capability of 48 minutes

Description

Patented gear and screw type pumps. These pumps are engineered for an extremely low coefficient of friction and are an excellent choice for mission-critical applications such as helicopters.

Hydrodynamic Bearings

Patented bearing offerings for extreme conditions

Description

Space Engine Systems offers thrust and radial bearings for extreme temperatures, high loads, and high speeds. Compact design is ideal for constrained spaces.

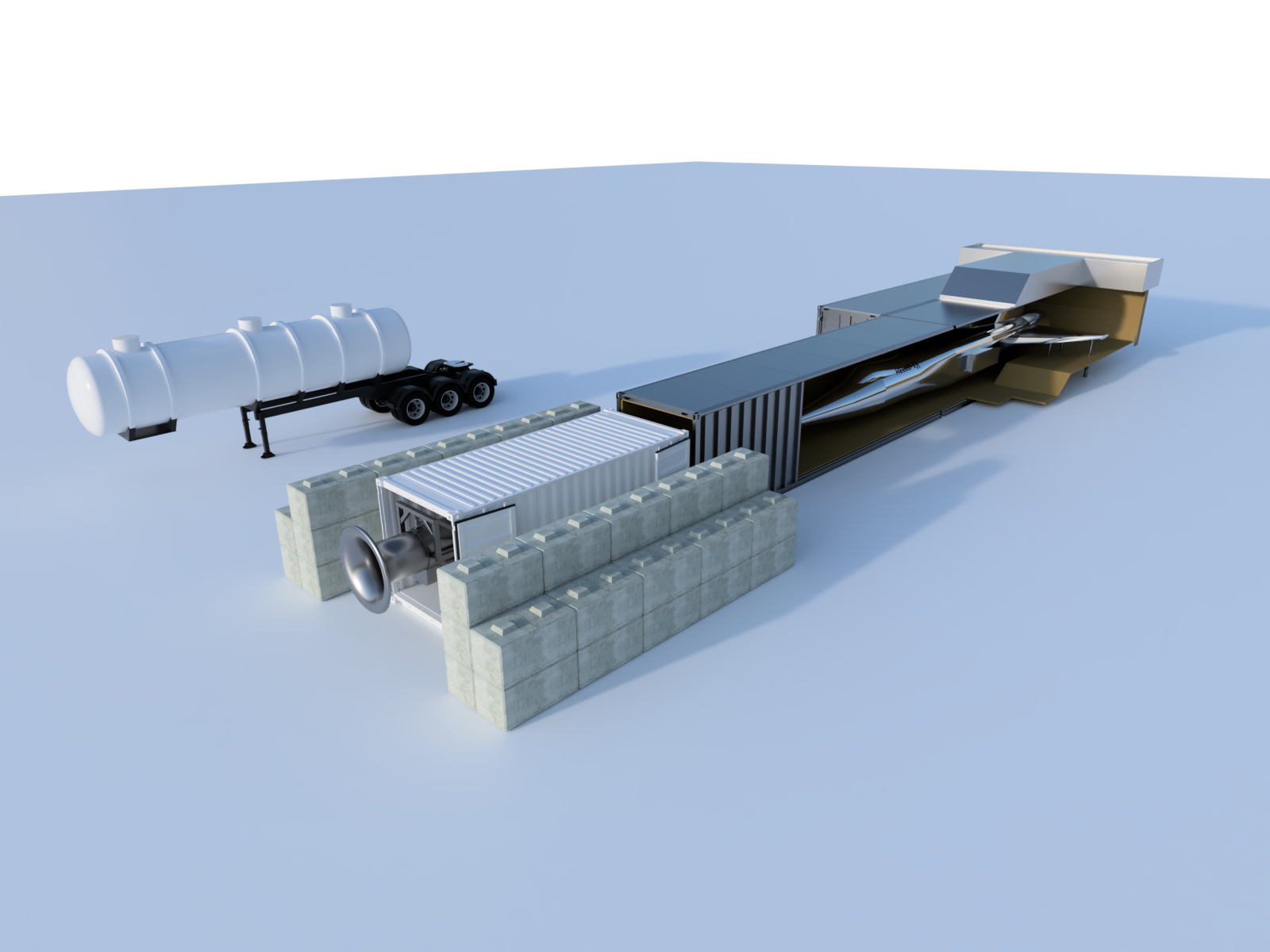

Turbine Engine Test Cell

Mobile test cell for up to 25,000 lbs thrust

Description

Test cell for afterburning turbojet engines up to 25,000 lbs thrust. Small footprint - fully enclosed in a 20 ft shipping container. Includes programmable fuel supply pump and conforms to SAE AIR4951 and AIR 5026B.

Heat Exchangers

High reliability heat exchangers for the most extreme conditions

Description

Our heat exchanger solutions are your most efficient option. Compatible with both high temperatures and cryogenic coolants, we can help you transfer in excess of 10 MW within 7.5 milliseconds. Additive manufacturing in sizes up to 1500 mm x 1500 mm x 600 mm.

HELLO-1X

Technology demonstrator vehicle

Description

The HELLO-1X is a piloted/optionally autonomous hypersonic demonstrator vehicle designed to cruise at a speed of Mach 5 and utilize liquid multi-fuel combustion. This aircraft is designed to take-off from a runway, climb to an altitude between 28 - 32 km, cruise at Mach 5, and glide return back to base. The vehicle will test our technologies at scale and ultimately lead the way for the development of HELLO-1 and HELLO-2.

Specifications

Cruise Altitude: 28 - 32 km (91,864 -104987 ft)

Cruise Speed: Mach 5

Capabilities

Flight systems testbed

Defense applications

Hypersonic research

Pilot training platform

Avionics testbed

DASS GNX

Turbo-Ramjet cycle engine

Description

The DASS GNX is a precooled, air-breathing, turbo-ramjet designed to meet the demands of hypersonic flight and will ultimately become the heart of both the HELLO-1 and HELLO-2 flight vehicles. Operating as an afterburning turbojet from zero to Mach 3 and a ramjet from Mach 3 to Mach 5, the DASS GNX can perform in a far wider range of conditions than either a turbojet or ramjet alone. The DASS GNX also features a precooler designed to significantly enhance thrust in turbojet mode and extend the operating range of the engine.

Specifications

Engine Operation: Pre-cooled afterburning turbo-ramjet

Sea level Static Thrust: 88.9 kN (20,000 lbf)

Specific Impulse: 3800 s

Capabilities

Non-toxic multi-fuel combustion

World’s First Full Scale Heated Wing Up Bending Test Facility (HAF Facility)

Airframe thermo-mechanical testing facility

Description

The HAF Facility is a facility designed to apply both thermal and mechanical loading to airframes at full scale with the purpose of gaining an understanding of how the airframe will perform under flight loads. This test cell will be completely mobile and capable of subjecting an airframe to temperatures approaching 1400 Celsius.

Specifications

Max temperature: 1400 C (2552 F)

Effective test cell length: 18.2 m (60 ft)

Thermal loading provided by 1 or more afterburning turbojet engines

Mechanical loading provided by an array of hydraulic cylinders

Load application rate between 30 - 60 s

80 kg/s mass flow rate. Additional flow can be added in multiples of 80 kg/s

Capabilities

Capable of applying loads representative of those experienced by a hypersonic aircraft during flight.

Capable of exceeding 135% of flight profile design loads at maximum cell operating temperature

Capable of exceeding 150% of flight profile design loads at ambient conditions

Test cell is completely mobile

HELLO-1

Commercial demonstrator vehicle

Description

The HELLO-1 spacecraft is a 100% reusable horizontal takeoff and landing spacecraft powered by 2 airbreathing DASS GNX engines and a single 445 kN (100,000 lbf) thrust class LH2/LO2 rocket engine. HELLO-1 is designed to fly a suborbital trajectory to an altitude of 100 km (63 mi) while attaining speeds in excess of Mach 5. At this altitude, HELLO-1 can deploy a transfer vehicle designed to carry customer payloads to low earth orbit. The first test flight is slated for 2023.

Specifications

Payload mass to LEO: 550 kg (1210 lbs)

Capabilities

Point to point transportation

Suborbital-return research flights

Suborbital-return crewed flights

Payload delivery to LEO

HELLO-2

Commercial space plane

Description

The HELLO-2 spacecraft is a 100% reusable horizontal takeoff and landing spacecraft powered by 4 to 6 airbreathing DASS GNX engines and a LH2/LO2 rocket engine. HELLO-2 is designed to boost heavy payloads to low earth orbit, geosynchronous equatorial orbit, and the lunar surface by way of a transfer vehicle released in low earth orbit.

Specifications

Payload Mass to Low Earth Orbit: 5500 kg (12,125 lbs)

Payload Mass to Geosynchronous Equatorial Orbit: 1730 kg (3810 lbs)

Payload Mass to Lunar Surface: 760 kg (1675 lbs)

Capabilities

Point to point transportation

Suborbital-return research flights

Suborbital-return crewed flights

Payload delivery to LEO

Payload delivery to GEO

Payload delivery to Lunar Surface

SEXBOMB

Technology demonstrator vehicle

Description

The SEXBOMB is a ramjet demonstrator vehicle designed to cruise at a speed of Mach 5 and utilize multi-fuel combustion of non-toxic liquid and solid propellants. This aircraft is designed to be launched from the underside of a supersonic fighter jet at an altitude of 15.24 km (50,000 ft) and a speed of Mach 1.8 where it will then climb to an altitude of 17.4 km and cruise at a speed of Mach 5. Powered flight will last for 300 seconds before the vehicle enters a glide phase back to base. This vehicle will test our ramjet, lifting body, and manufacturing technologies at scale.

Specifications

Cruise Altitude: 17.4 km (57,000 ft)

Cruise Speed: Mach 5

Capabilities

Flight systems testbed

Defense applications

Hypersonic research